Custom Printed Bags for Food Manufacturers

At UPAC, we specialise in creating custom-printed plastic and paper bags for the food and beverage industry

UPAC offers world-class facilities and Australian manufacturing to produce and print custom-printed bags.

With over 49 years of expertise in creating custom-made bags, UPAC ensures that each printed plastic and paper bag enhances your brand, increases packaging efficiency, and meets the specific technical requirements of your products.

The DURAPLAS range of plastic and paper bags is manufactured to the highest standard of food safety. Designed for direct food contact, these bags are backed by UPAC’s HACCP accreditation, guaranteeing their safety. Made from virgin food-grade plastic or paper, DURAPLAS bags enhance the shelf life of baked and frozen products by effectively regulating moisture and airflow around the food.

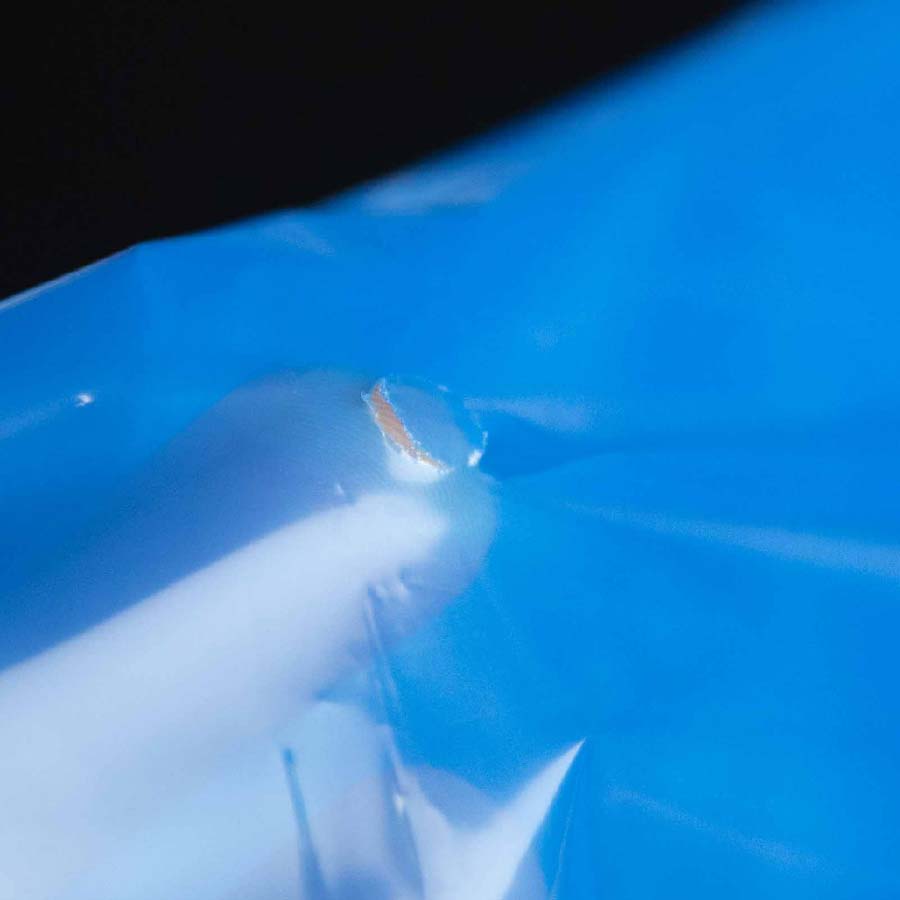

At UPAC, we take pride in providing innovative bag solutions for ice manufacturers. Our printed bag specialists collaborate directly with your team to bring any ice packaging vision to life through custom-printed bags. We believe no option is impossible. Whether it's thickness, length, punching, wickets, custom-branded designs, or Gravure CMYK printing - whatever challenges you face, UPAC will provide the solution.

We take great pride in performing thorough quality checks to ensure that every detail and bag specification is met, giving your team peace of mind throughout the custom-printed ice bag process. Ice manufacturers can choose from a range of low-density polyethylene (LDPE) compositions for ice bags, tailored to your unique needs. Our food-safe ice bags are made from virgin, food-safe materials and are free from bisphenol A (BPA), phthalates, and epoxidised soybean oil (ESBO).

Our Custom-made Food Bag Features

Gussets

We can incorporate custom size side or bottom gussets to enhance product fit.

Thickness

Low-density polyethylene (LDPE) resins are extruded to a specified thickness, creating an ice bag tailored to your unique application.

Venting

Unique hole punching allows for effective air release.

Wicketing

We offer 4″, 5″, 6″, 7″, or 8″ wire wickets, crimped headers, and wicket fail points, with side seam slit stoppers.

Material Colours

We can tint or fully colour any ice bag material using a formulated master batch to enhance your brand and protect your product.

Material types

We offer custom-made plastic bags composed of mono-layer food-grade LLDPE and co-extrusion. A fully customised composition of resins and additives ensures the ice bags are unique to your application and can withstand sub-zero temperatures for extended periods.

Printing

We provide 1 to 12-colour flexographic printing, or up to full 8-colour Gravure CMYK printing – perfect for custom-printed and seasonal-themed ice bags. Stand out from the crowd this Christmas!

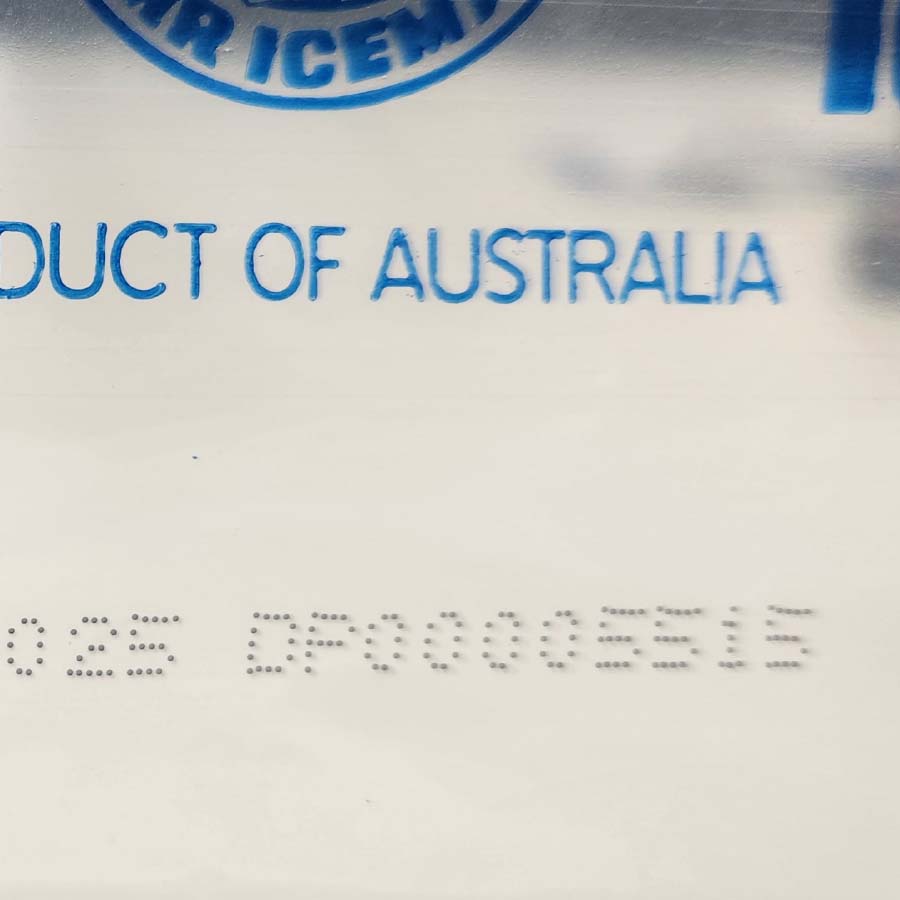

Sequential Numbering

We offer best-before dates, batch codes, and digital sequential numbering for traceability and food safety records, ensuring swift and effective ice production tracking.

Certified Bags

Our UPAC bag specialists excel in delivering food-safe solutions for the food and beverage industry.

DURAPLAS custom-made bags are certified safe for food contact and are produced and stored in facilities that implement a HACCP plan. We undergo regular audits to ensure compliance with food safety regulations. This rigorous certification process, along with our strict adherence to food safety guidelines, guarantees that our plastic and paper bags meet the highest safety standards.

You can trust that DURAPLAS bags are safe for both food storage and transportation.

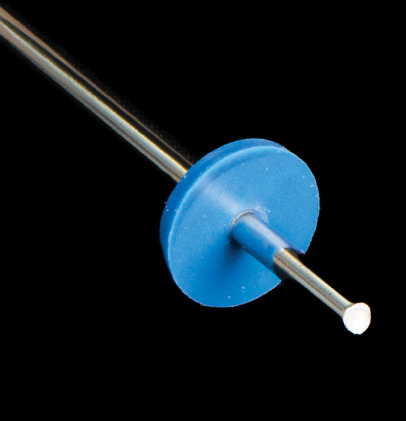

Wire Wickets

Wire wickets and coloured grommets on wicketed plastic bags play a crucial role in the food industry, and their high quality is essential for maintaining food safety.

We design these components specifically for food-safe environments, using high-quality materials and meticulous attention to detail to ensure their suitability for food products.

The coloured grommets also help prevent cross-contamination and enhance food safety practices, making them vital in bread, ice, and produce bagging environments.

Bag Loading

Efficient bag loading is critical to the success of food production operations.

Through years of development and testing, UPAC has enhanced food loading efficiencies, eliminated tail-ends, reduced waste, and improved overall productivity.

By identifying and addressing these strategic challenges, we have helped bakeries, ice plants, and produce growers streamline their operations and succeed in a high-speed, highly competitive industry.

Ethical Practices

UPAC is committed to maintaining safe practices across the entire food industry.

We believe in fostering ethical partnerships by ensuring that all materials sourced globally come from suppliers who meet our standards for ethical production, fair labour conditions, and environmental responsibility.

By providing high-quality, food-safe, custom-made plastic bag solutions, we help ensure the safety and integrity of the food products that millions of people consume every day.

Custom Printed Plastic Bag Specialists

We can fully customise DURAPLAS plastic bags to enhance both your product and brand.

Choose from a variety of options, including material, thickness, strength, size, style, artwork design, and print. At UPAC, we offer a wide range of features to meet your exact product requirements, including wicketed, punched, non-slip, gusseted, resealable, tamper-evident, printed, and write-on panel bag options. Elevate your brand with food packaging that’s uniquely yours.

To get started, simply fill out our quote request form, and we’ll promptly provide a custom quote for plastic or paper bags tailored to your needs.

UPAC Smart Inventory Efficiency System

Enabling Australian Manufacturers to GROW Through Managed Inventory.

With our UPAC Inventory Management Program, VENDURA, we manage a complete forecasted supply and warehousing solution. This program ensures an on-demand supply of your custom-printed plastic bags & custom-printed paper bags from HACCP-accredited facilities.

Never run out of stock or be forced to sacrifice your manufacturing floor space for the storage of bulk custom-made packaging.

How it works

This system relieves pressure on your space, cash flow, and team.

UPAC & The Environment

At UPAC, we care about the environment and your business. Our printed plastic bags feature clear, easily recognisable recycling symbols, empowering your customers to make responsible recycling decisions. This simple step helps reduce the likelihood of plastic bags ending up in landfills.

If you are a food manufacturer with a HACCP Food Safety Program, UPAC offers approved printed plastic bag options to ensure your food packaging complies with the guidelines. We package DURAPLAS custom plastic bags and custom paper bags hygienically to prevent contamination and meet HACCP standards. Our custom made bags are certified safe for food contact and are produced and stored in facilities that implement a HACCP plan.

CONTACT UPAC TODAY